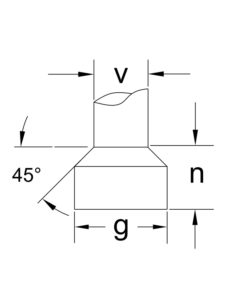

| Spiral Gaskets | Recommended Mounting Dimensions | Dovetail Cutter Dimensions | ||||||

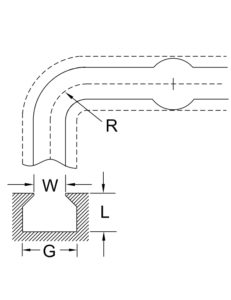

| Cutter P/N | Use on Gasket P/N* | L +.002” -.000” | G +.007” -.005” | W +.000” -.002” | n +.000” -.002” | g +.005” -.003” | v +.000” -.002” | Shank Dia. |

| GC-1-02-C | -02 | .023” | .046” | .033” | .024” | .046” | .027” | 0.1875” |

| GC-1-03-C | -03 | .035” | .063” | .045” | .037” | .063” | .035” | 0.1875” |

| GC-1-04B-C | -04 | .046” | .094” | .060” | .046” | .094” | .050” | 0.1875” |

| GC-1-.070-C | -.070 | .053” | .094” | .067” | .054” | .094” | .055” | 0.1875” |

| GC-1-05B-C | -05 | .059” | .109” | .075” | .060” | .109” | .063” | 0.1875” |

| GC-1-06-C | -06 | .070” | .125” | .090” | .072” | .125” | .076” | 0.1875” |

| GC-1-.103-C | -.103 | .077” | .141” | .099” | .078” | .141” | .085” | 0.1875” |

| GC-1-07B-C | -07 | .082” | .156” | .105” | .080” | .156” | .095” | 0.1875” |

| GC-1-08-C | -08 | .094” | .171” | .121” | .097” | .171” | .101” | 0.1875” |

| GC-1-.139-C | -.139 | .104” | .187” | .134” | .114” | .187” | .106” | 0.1875” |

| GC-1-09-C | -09 | .105” | .187” | .136” | .106” | .187” | .120” | 0.1875” |

| GC-1-11-C | -11 | .128” | .234” | .165” | .130” | .234” | .145” | 0.1875” |

| GC-1-12-C | -12 | .140” | .250” | .181” | .148” | .250” | .145” | 0.375” |

| GC-1-16B-C | -16 | .185” | .343” | .240” | .185” | .343” | .230” | 0.375” |

| GC-1-20-C | -20 | .234” | .422” | .300” | .234” | .406” | .270” | 0.5” |

| GC-1-24-C | -24 | .280” | .500” | .364” | .281” | .500” | .334” | 0.5” |

| GC-1-32-C | -32 | .375” | .656” | .485” | .378” | .656” | .438” | 0.6875” |

| “D” Multi-Seal Groove Cutters | ||||||||

| DGC-1-04-C | -0421 | .046” | .187” | .138” | .052” | .187” | .118” | 0.1875” |

| DGC-1-06-C | -0632 | .070” | .250” | .180” | .075” | .250” | .160” | 0.375” |

| DGC-1-08B-C | -0842 | .094” | .313” | .240” | .087” | .313” | .230” | 0.375” |

| DGC-1-12-C | -1263 | .140” | .500” | .367” | .146” | .500” | .337” | 0.5” |

| DGC-1-16-C | -1684 | .188” | .625” | .485” | .193” | .625” | .455” | 0.625” |

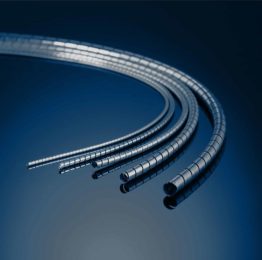

* Cutter dash numbers correspond one-on one to all Spira-Shield, Ultra Quick Shield, Quick-Shield, Flexi-Shield, Enduro-Shield &

“D” Multi-Seal dash numbers. Example: SS-08 uses a GC 1-08-C cutter.