Application

What is the longest Enduro-Shield continuous length and how are the ends connected?

Enduro-Shield is manufactured in 4’ lengths, but can be ordered in lengths as long as 100’. We butt-join the 4’ lengths with a pin and glue them in place using the same adhesive as the internal core (silicone is standard, but other options are available).

Can customers splice Enduro-Shield?

How expensive are your gaskets?

I need to shield an air vent, do you have anything that will work?

Does it come in rolls or cut to length?

Will pieces break off like other gaskets I’ve tried for VME applications?

Shielding Quality

What is the Shielding Quality of Spira EMI Gaskets at high frequencies?

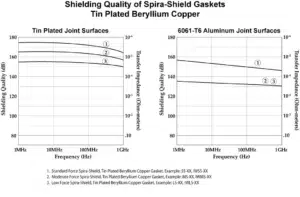

We have some of this information on our website here. If you scroll down, you’ll see some charts that show the shielding quality with different materials and such. Most of our testing (all of the graphs on the website) is done up to 1 GHz. This is mainly driven by the setup needed to be able to test at higher frequency ranges. But, we have found that as a worst-case scenario, you can estimate a decline of 20 dB per frequency decade.

Please see below for a screenshot of one of those graphs from our website for an example. If you look at the tin-plated joint surfaces, at 1 GHz for curve (1), you are seeing about 165 dB. This would mean that in a worst-case scenario, you would have about 145 dB at 10 GHz and 125 dB at 100 GHz. So your requirement of 40 dB should not be a problem.

Please contact us if you have any questions.

What is the Shielding Quality if my design doesn’t compress the spiral to the recommended 25% of its diameter?

Spira Part Installation

What is the standard recommended roughness of a groove?

The flatness between the bottom of the groove and the top surface must be held flat within ± .001”

How many times can you compress a gasket to 25% compression?

How much can you compress each gasket before permanent deformation?

What is the minimum bend radius for groove?

Can I use sharp corners in my groove and butt-join the spiral ends up against each other?

How easy is it to insert the Flexi-Shield gasket into VME type panels?

Are the gaskets easy to install?

Materials

What is the overall length of Dovetail Groove Cutters?

2” in overall length.

How much do Front-Mount and Back-Mount EMI & Environmental Connector-Seal frames compress when fully torqued?

How are the Transfer Impedance fixtures configured?

How are spiral gaskets spliced for spooling?

Can we use nickel plating in space?

Can we use spiral gaskets with anodized surfaces?

What is the thickness of plating?

When purchasing cut-to-length spiral gaskets are the ends also plated?

What is the sub-specification for Spira parts that are made from beryllium copper?

Is there acetic acid in some adhesives?

Is standard force spiral used for honeycomb filters?

Can I get low force with .034” spiral?

Why choose fluorosilicone vs. silicone?

Can I order unplated beryllium copper spiral?

Customization

What are the tradeoffs between Die-Cut Gaskets and Framed Gaskets?

Both are available in custom configurations, manufactured to your specifications.

Typically, Die-Cut Gaskets are more cost-effective once you need 15 pieces or more. For less than that, Framed Gaskets are often more cost-effective. The thickness of the rubber is driven by spiral diameter. Please refer to the rubber thickness of our Spira-Strip and Quick-Strip gaskets for reference.

Framed gaskets can also yield a lower compression environmental seal using our Basic Multi-Seal gasket.